Manufacturing Supply Chain Optimization Techniques

Overview of Manufacturing Supply Chains

It encompasses the procurement of raw materials, production processes, inventory management, and distribution of finished goods. An optimized manufacturing supply chain is critical for reducing costs, improving efficiency, and meeting customer demands.

In the highly competitive manufacturing industry, companies must continuously strive to enhance their supply chain operations. Effective supply chain management ensures that products are manufactured and delivered on time, minimizing delays and reducing costs.

Techniques for Supply Chain Optimization

Optimizing the supply chain involves implementing various techniques to improve efficiency, reduce costs, and enhance overall performance. Here are some key techniques for supply chain optimization:

1. Demand Forecasting

Accurate demand forecasting is essential for optimizing the supply chain. By analyzing historical sales data, market trends, and customer behavior, businesses can predict future demand and adjust their production and inventory levels accordingly. Advanced analytics and machine learning algorithms can enhance the accuracy of demand forecasts.

2. Inventory Management

Effective inventory management ensures that the right amount of inventory is available at the right time. Techniques such as Just-In-Time (JIT) inventory, safety stock management, and inventory optimization models help in maintaining optimal inventory levels, reducing carrying costs, and preventing stockouts and overstock situations.

3. Supplier Collaboration

Collaborating closely with suppliers can enhance supply chain efficiency. Establishing strong relationships with suppliers, sharing demand forecasts, and collaborating on production schedules can improve coordination and reduce lead times. Supplier collaboration also enables better negotiation of prices and terms.

4. Lean Manufacturing

Lean manufacturing focuses on eliminating waste and improving efficiency in the production process. Techniques such as value stream mapping, continuous improvement (Kaizen), and 5S (Sort, Set in order, Shine, Standardize, Sustain) help in identifying and eliminating non-value-added activities, reducing costs, and improving productivity.

5. Technology Integration

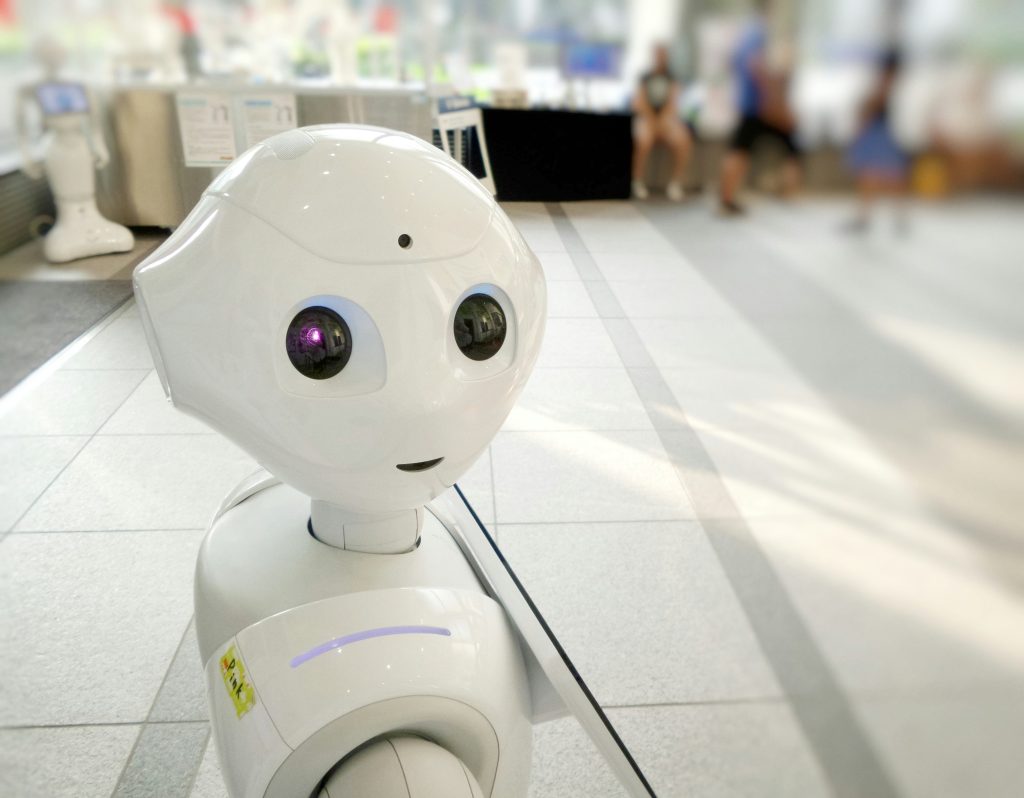

Integrating advanced technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and automation into the supply chain software can significantly improve efficiency. IoT devices can monitor equipment and inventory in real-time, AI can optimize production schedules and demand forecasts, and automation can streamline repetitive tasks.

Managing Supply Chains in Manufacturing

Effective management of supply chains in manufacturing involves coordinating various processes and stakeholders to ensure smooth operations. Here are some key aspects of managing supply chains in manufacturing:

Production planning involves scheduling production activities to meet customer demand while optimizing resource utilization. This includes determining the production schedule, allocating resources, and managing work-in-progress inventory. Advanced planning and scheduling (APS) systems can help in optimizing production plans.

Procurement management involves sourcing raw materials and components needed for production. Effective procurement management ensures that materials are available when needed, at the right price, and of the right quality. This includes supplier selection, contract management, and purchase order management.

Logistics and distribution involve the transportation and storage of raw materials, work-in-progress inventory, and finished goods. Efficient logistics and distribution management ensure timely delivery of materials and products, minimizing delays and reducing transportation costs. This includes optimizing transportation routes, managing warehouses, and coordinating with logistics providers.

Quality control ensures that products meet the required standards and specifications. Implementing quality control measures throughout the production process helps in identifying and addressing defects, reducing rework and scrap, and ensuring customer satisfaction. This includes inspecting raw materials, monitoring production processes, and conducting final product inspections.

Monitoring the performance of the supply chain is essential for identifying areas for improvement. Key performance indicators (KPIs) such as on-time delivery, order fulfillment accuracy, and production efficiency provide insights into the effectiveness of supply chain operations. Regular performance reviews and audits help in identifying and addressing inefficiencies.

Improving Efficiency in Supply Chains

Improving efficiency in supply chains involves implementing various strategies to streamline operations, reduce costs, and enhance productivity.

Here are some key strategies for improving efficiency in supply chains:

Optimizing processes involves analyzing and improving workflows to eliminate bottlenecks and reduce cycle times. Techniques such as process mapping, Six Sigma, and Total Quality Management (TQM) help in identifying and addressing inefficiencies, improving process reliability, and enhancing overall productivity.

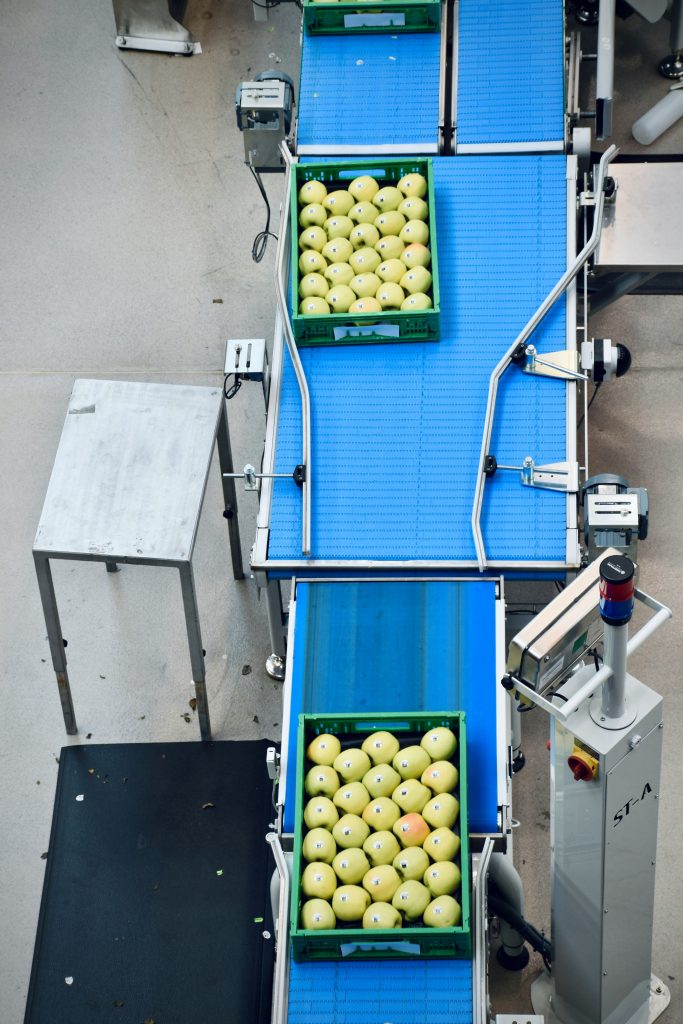

Automation involves using technology to perform repetitive tasks, reducing the need for manual intervention and minimizing errors. Implementing automation in areas such as inventory management, order processing, and production can significantly improve efficiency and reduce costs. This includes using automated guided vehicles (AGVs), robotic process automation (RPA), and automated storage and retrieval systems (AS/RS).

Data analytics provides valuable insights into supply chain operations, helping businesses make data-driven decisions. By analyzing data from various sources, such as sensors, ERP systems, and customer feedback, businesses can identify trends, optimize processes, and predict future needs. Advanced analytics tools and techniques, such as predictive analytics and machine learning, enhance the accuracy and effectiveness of data analysis.

Collaborative planning involves working closely with suppliers, customers, and other stakeholders to align supply chain activities and improve coordination. Techniques such as Sales and Operations Planning (S&OP) and Collaborative Planning, Forecasting, and Replenishment (CPFR) help in synchronizing supply chain activities, reducing lead times, and improving responsiveness.

Implementing sustainability practices in the supply chain helps in reducing environmental impact and improving efficiency. This includes using energy-efficient technologies, reducing waste, and sourcing materials from sustainable suppliers. Sustainability practices not only benefit the environment but also enhance the company’s reputation and compliance with regulations.

Advanced Strategies for Supply Chain Management

Advanced strategies for supply chain management involve leveraging cutting-edge technologies and innovative practices to achieve higher levels of efficiency and performance. Here are some advanced strategies for supply chain management:

1. Blockchain Technology

Blockchain technology provides a secure and transparent way to track transactions and information throughout the supply chain. By creating an immutable record of transactions, blockchain enhances transparency, reduces fraud, and improves traceability. This technology is particularly useful for tracking the origin and authenticity of raw materials and finished goods.

2. Artificial Intelligence (AI)

AI can be used to optimize various aspects of the supply chain, such as demand forecasting, inventory management, and production scheduling. AI algorithms analyze large datasets to identify patterns and trends, enabling businesses to make more accurate and informed decisions. AI-powered systems can also automate complex tasks and improve overall efficiency.

3. Internet of Things (IoT)

IoT devices provide real-time data on various aspects of the supply chain, such as equipment performance, inventory levels, and environmental conditions. This data can be used to monitor and optimize operations, improve maintenance schedules, and enhance visibility. IoT-enabled supply chains are more responsive and agile, enabling businesses to quickly adapt to changing conditions.

4. Advanced Robotics

Advanced robotics, such as collaborative robots (cobots) and autonomous mobile robots (AMRs), can perform tasks with high precision and efficiency. These robots can work alongside human workers, enhancing productivity and reducing labor costs. Advanced robotics can be used in areas such as production, warehousing, and distribution to streamline operations.

5. Digital Twins

Digital twins are virtual replicas of physical assets, processes, or systems. By creating a digital twin of the supply chain, businesses can simulate and analyze different scenarios, identify potential issues, and optimize operations. Digital twins provide a comprehensive view of the supply chain, enabling proactive management and continuous improvement.

How Linbis Helps Companies with Supply Chain Optimization

Linbis offers comprehensive supply chain management solutions designed to optimize logistics operations and improve efficiency. Here’s how Linbis can support your supply chain optimization needs:

Advanced Supply Chain Management Software

Linbis provides state-of-the-art supply chain management software that offers comprehensive tools for managing all aspects of the supply chain. Our software integrates seamlessly with other business systems, streamlining processes and improving efficiency.

Real-Time Data and Analytics

Our analytics tools provide real-time insights into supply chain operations, helping businesses make data-driven decisions. Linbis offers advanced analytics and reporting tools that track key performance indicators (KPIs) and provide actionable insights for continuous improvement.

Automation and Technology Integration

Linbis distribution management software integrates with advanced technologies, such as IoT, AI, and automation, to enhance supply chain operations. Our solutions include real-time monitoring, predictive analytics, and automation tools that improve efficiency and reduce costs.

Collaborative Planning Tools

Linbis offers collaborative planning tools that help businesses align supply chain activities with suppliers, customers, and other stakeholders. Our tools support Sales and Operations Planning (S&OP) and Collaborative Planning, Forecasting, and Replenishment (CPFR) processes, enhancing coordination and responsiveness.

Customizable Solutions

Linbis supply chain management software is highly customizable and can be tailored to meet the specific needs of your business. This ensures a smooth implementation and enhances the overall efficiency of supply chain operations.

FAQ

What is supply chain optimization?

Supply chain optimization involves implementing various techniques and strategies to improve the efficiency, reduce costs, and enhance the overall performance of the supply chain. This includes demand forecasting, inventory management, supplier collaboration, and process optimization.

How can technology improve supply chain management?

Technology can improve supply chain management by providing real-time data, automating tasks, and enhancing visibility. Advanced technologies such as IoT, AI, and automation streamline operations, reduce costs, and improve decision-making.

What are the benefits of supplier collaboration?

Supplier collaboration enhances coordination, reduces lead times, and improves supply chain efficiency. Establishing strong relationships with suppliers, sharing demand forecasts, and collaborating on production schedules lead to better pricing, terms, and overall performance.

How can Linbis help with supply chain optimization?

Linbis offers advanced supply chain management solutions, including state-of-the-art software, real-time data and analytics, automation and technology integration, collaborative planning tools, and customizable solutions. These features help businesses optimize their supply chain operations, reduce costs, and improve efficiency.

What are some advanced strategies for supply chain management?

Advanced strategies for supply chain management include leveraging blockchain technology for transparency and traceability, using artificial intelligence for demand forecasting and inventory optimization, implementing Internet of Things (IoT) devices for real-time monitoring, employing advanced robotics for automation, and utilizing digital twins for simulation and proactive management.

Conclusion

Optimizing the manufacturing supply chain is crucial for reducing costs, improving efficiency, and meeting customer demands. By implementing effective techniques, managing supply chains efficiently, improving operational efficiency, and adopting advanced strategies, businesses can achieve higher levels of performance and competitiveness.

Linbis offers comprehensive supply chain management solutions designed to support your logistics needs. For more information on how Linbis can help streamline your supply chain operations and improve efficiency, visit our Supply Chain Management Software page and explore our advanced solutions tailored to meet your business requirements.