WMS Implementation Guide: From Setup to Success

🚦 Step 1: Define Your Goals and Needs

Before choosing or configuring your WMS, start with clarity:

- What warehouse challenges are you solving?

- Are you focused on inventory accuracy, faster picking, or reducing manual tasks?

- Do you need integrations (ecommerce, TMS, ERP)?

🎯 Tip: Align software features with your operational priorities from day one.

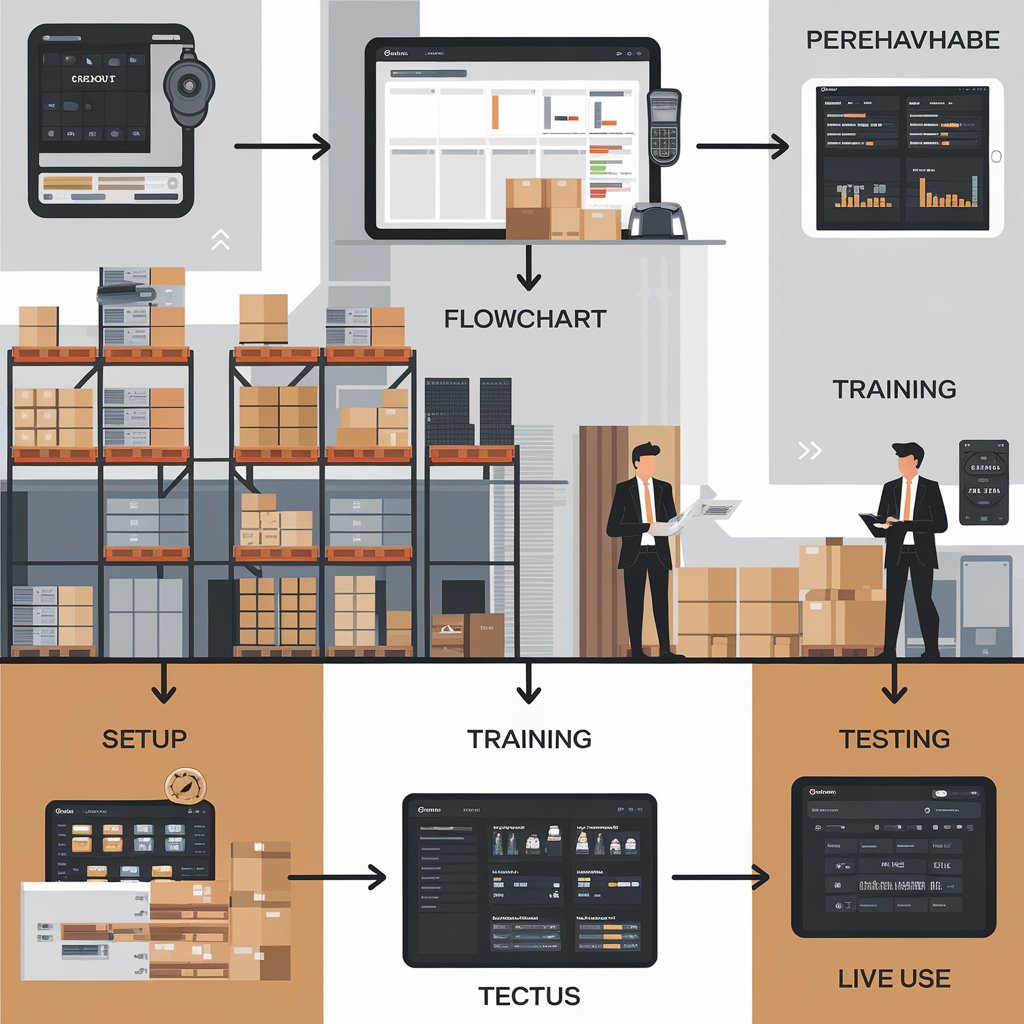

🧩 Step 2: Map Out Your Warehouse Workflows

A successful WMS adapts to your flow — not the other way around. Document your current warehouse operations:

- Inbound (receiving, put-away)

- Storage and bin systems

- Picking and packing methods

- Shipping and dispatch

- Returns and cycle counting

📌 Pro tip: Identify process bottlenecks and look for automation opportunities during this stage.

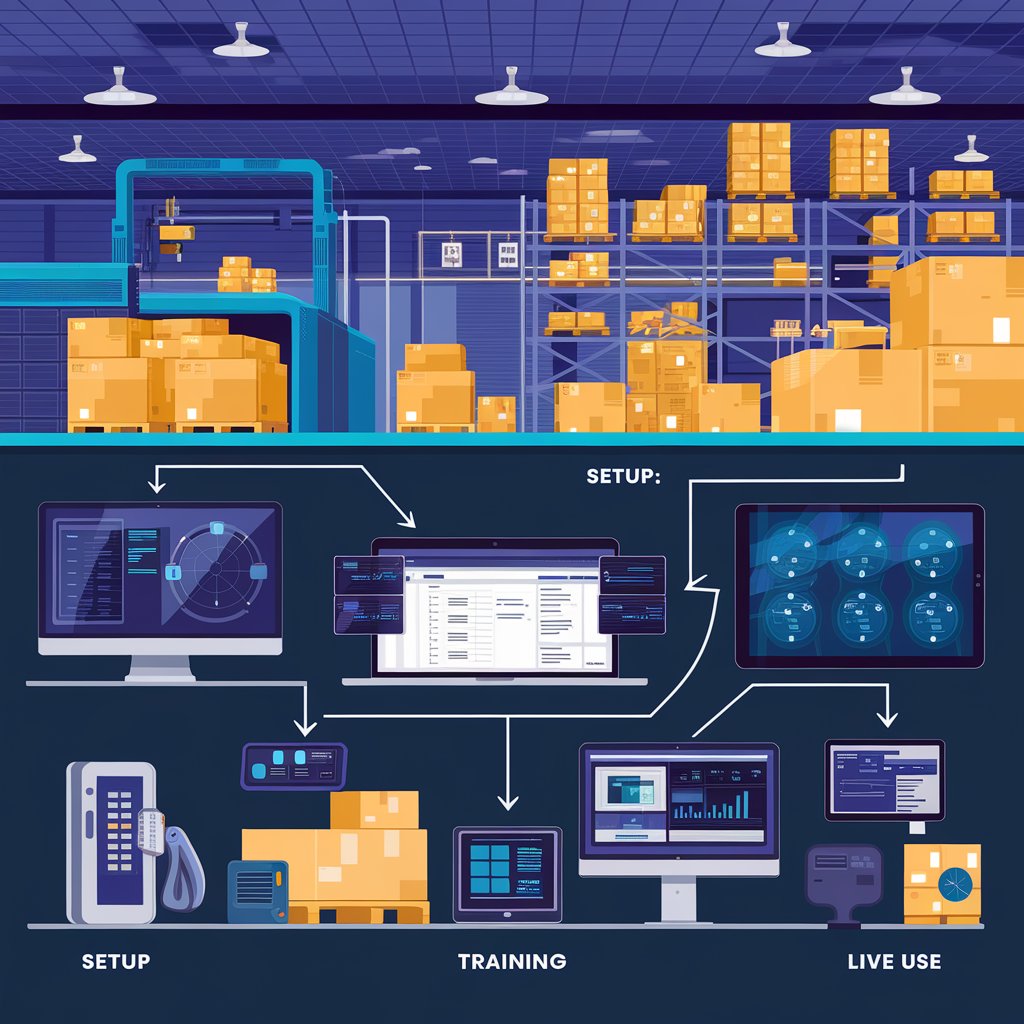

🖥️ Step 3: System Configuration and Setup

Now it’s time to configure your WMS based on your mapped workflows.

- Set up warehouse zones and bin locations

- Upload SKUs and product attributes

- Define user roles and permissions

- Configure scanning devices and hardware

- Connect to external platforms (ecommerce, TMS, ERP)

⚙️ Note: This stage is often smoother with a provider that offers clear onboarding documentation or guided setup.

👨🏫 Step 4: Staff Training

A great WMS is only as effective as the team using it.

- Train staff on how to use the interface

- Practice picking, receiving, and labeling tasks

- Run mock orders to simulate real workflows

- Provide quick-reference guides and support access

📚 Tip: Focus on team buy-in — warehouse staff are your power users.

🧪 Step 5: Test Before You Go Live

Run a controlled pilot phase before full launch:

- Test integrations and real-time syncing

- Validate inventory movement and system accuracy

- Identify any user confusion or technical glitches

🧭 Goal: Resolve issues in a sandbox before impacting customers or operations.

🚀 Step 6: Go Live (Gradually)

Launch in phases if possible:

- Start with a single zone or product line

- Monitor performance metrics daily

- Adjust rules and permissions as needed

🔄 Tip: Keep your old system on standby temporarily during the transition.

📊 Step 7: Monitor, Optimize, and Scale

After launch, continue tracking:

- Inventory accuracy

- Order fulfillment speed

- Error rates and return reasons

- User activity and productivity

Use this data to refine processes, retrain staff, and scale the system as your operation grows.

🧭 Common WMS Implementation Pitfalls to Avoid

❌ Skipping the planning stage

❌ Not involving warehouse staff in testing

❌ Failing to integrate with existing systems

❌ Underestimating training time

❌ Going live all at once with no fallback

🏁 Final Thoughts

A successful WMS implementation is not just about installing software — it’s about transforming your operations with the right strategy, training, and support. By following a structured rollout plan, you’ll reduce friction, empower your team, and set your warehouse up for long-term efficiency.