How a Small Company Can Implement Manufacturing Management Software

Implementing manufacturing management software in a small business can transform operations, improve efficiency, and reduce costs. Here’s a step-by-step guide to successfully integrate this software into your business:

Step 1: Assess Your Business Needs for Manufacturing Management Software

Identify Key Areas for Improvement

Inventory Management: Do you often face issues with overstocking or stockouts?

Production Planning: Are there frequent delays in your production schedules?

Quality Control: Do you struggle with maintaining consistent product quality?

Example:

A small furniture manufacturer often faces delays due to inefficient production scheduling and frequent stockouts of key materials like wood and fabric.

Action:

List specific challenges and prioritize them based on their impact on your operations. Find a good logistics software for your small business

Step 2: Choose the Right Manufacturing Management Software

Evaluate Software Options

Look for software that offers:

- Scalability: Can grow with your business.

- Flexibility: Offers modules you can add as needed.

- User-Friendly Interface: Easy for your team to learn and use.

Example:

The small furniture manufacturer needs software that integrates inventory management and production scheduling with a user-friendly interface.

Action:

Research and compare different software options. Consider features, pricing, and customer reviews. Schedule demos to see the software in action.

Step 3: Plan the Implementation

Create an Implementation Timeline for Manufacturing Management Software

Initial Setup: Allocate time for setting up the manufacturing management software, including data migration and system configuration.

Training: Schedule comprehensive training sessions for your team.

Go-Live: Plan a phased rollout to minimize disruptions.

Example:

The small furniture manufacturer plans a three-month implementation period, starting with inventory management, followed by production scheduling.

Action:

Develop a detailed timeline with specific milestones and deadlines. Ensure all stakeholders are aware of their roles and responsibilities.

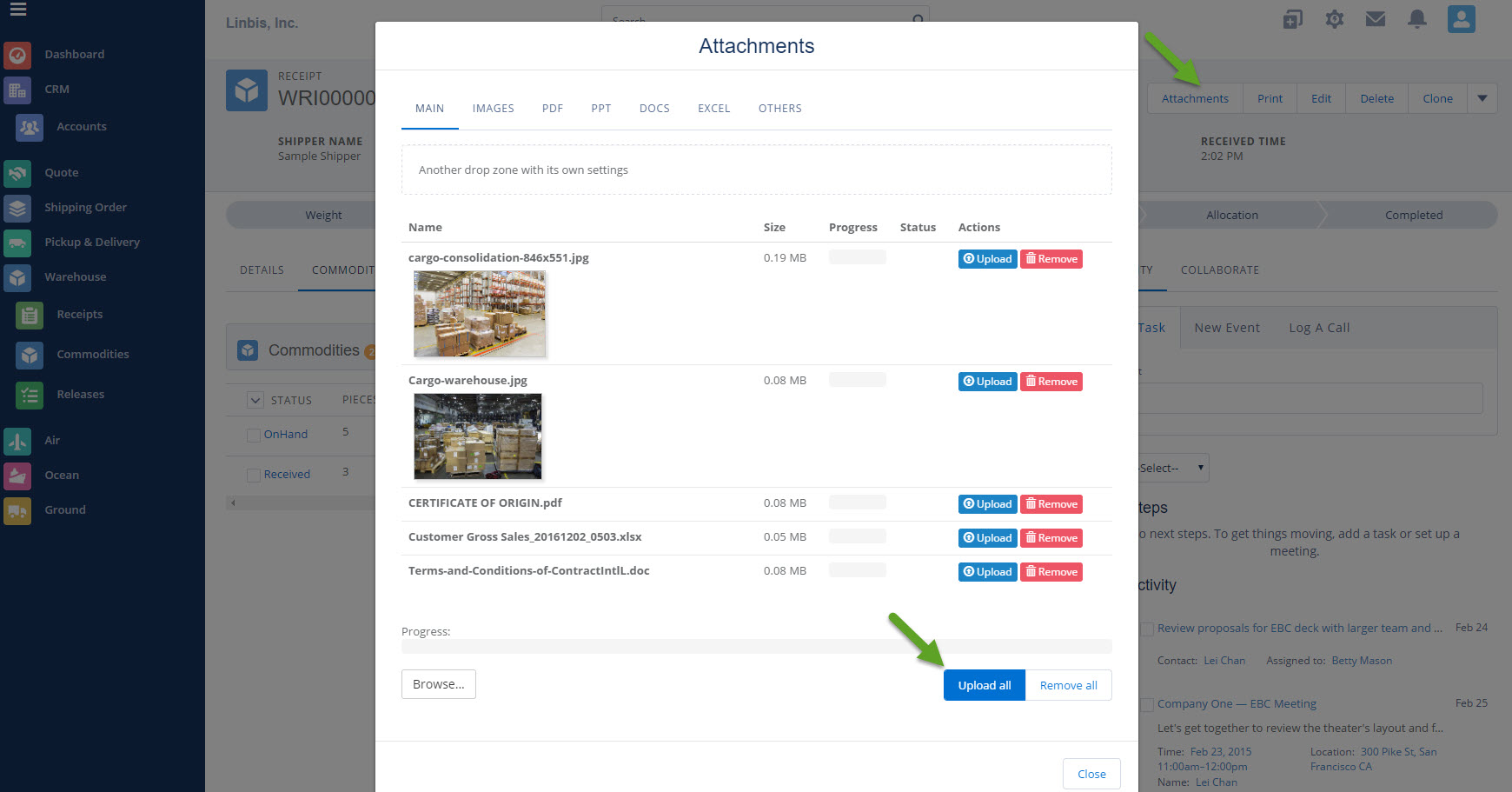

Step 4: Data Migration and System Configuration

Prepare Your Data

Inventory Data: Ensure all inventory data is accurate and up-to-date.

Production Data: Compile data on current production schedules and processes. Add data to the manufacturing management software

Example:

The small furniture manufacturer compiles an accurate list of current inventory and detailed production workflows.

Action:

Work with your software provider to migrate data into the new system. Configure the software settings to match your specific business needs. Make sure to add all your customers to your logistics crm.

Step 5: Train Your Team

Comprehensive Training Sessions

Initial Training: Provide hands-on training sessions to familiarize your team with the software.

Ongoing Support: Establish a support system for ongoing training and troubleshooting.

Example:

The small furniture manufacturer schedules weekly training sessions for the first month, focusing on different modules of the software.

Action:

Create a training plan with clear objectives. Use a combination of in-person training, online tutorials, and documentation.

Step 6: Monitor and Optimize a Manufacturing Management Software

Regularly Review Performance

Performance Metrics: Track key performance indicators (KPIs) such as production efficiency, inventory levels, and product quality.

Feedback Loop: Collect feedback from your team to identify areas for improvement.

Example:

The small furniture manufacturer monitors inventory turnover rates and production lead times, making adjustments as needed by using a warehouse management system

Action:

Set up regular review meetings to analyze performance data and discuss feedback. Continuously refine your processes based on insights gained.

Step 7: Scale and Expand

Add New Modules as Needed

Advanced Features: Explore additional features such as predictive maintenance or advanced analytics.

Integration: Ensure seamless integration with other business systems like ERP or CRM.

Example:

After successfully implementing inventory and production modules, the small furniture manufacturer adds quality control features.

Action:

Regularly assess your business needs and explore opportunities to enhance your software capabilities.

Conclusion

Implementing manufacturing management software in a small business involves a thorough assessment of needs, careful planning, and continuous optimization. By following these steps, small companies can leverage this technology to improve efficiency, reduce costs, and enhance overall productivity.

For further assistance, contact Linbis today to learn more about our tailored manufacturing management solutions and request a demo for Linbis supply chain management software.