Robotics in Warehousing: Impact on Freight and 3PL Operations

🚛 Why Robotics in Warehousing Matters Now

Warehousing has traditionally been labor-intensive and time-consuming. But in recent years, robotics has entered the space to solve pain points such as:

- Labor shortages and rising wages

- Order fulfillment bottlenecks

- Human error in inventory handling

- Growing SKU complexity in fulfillment centers

With robotics, warehouses can scale faster, fulfill more orders, and reduce operational costs—all while maintaining high accuracy.

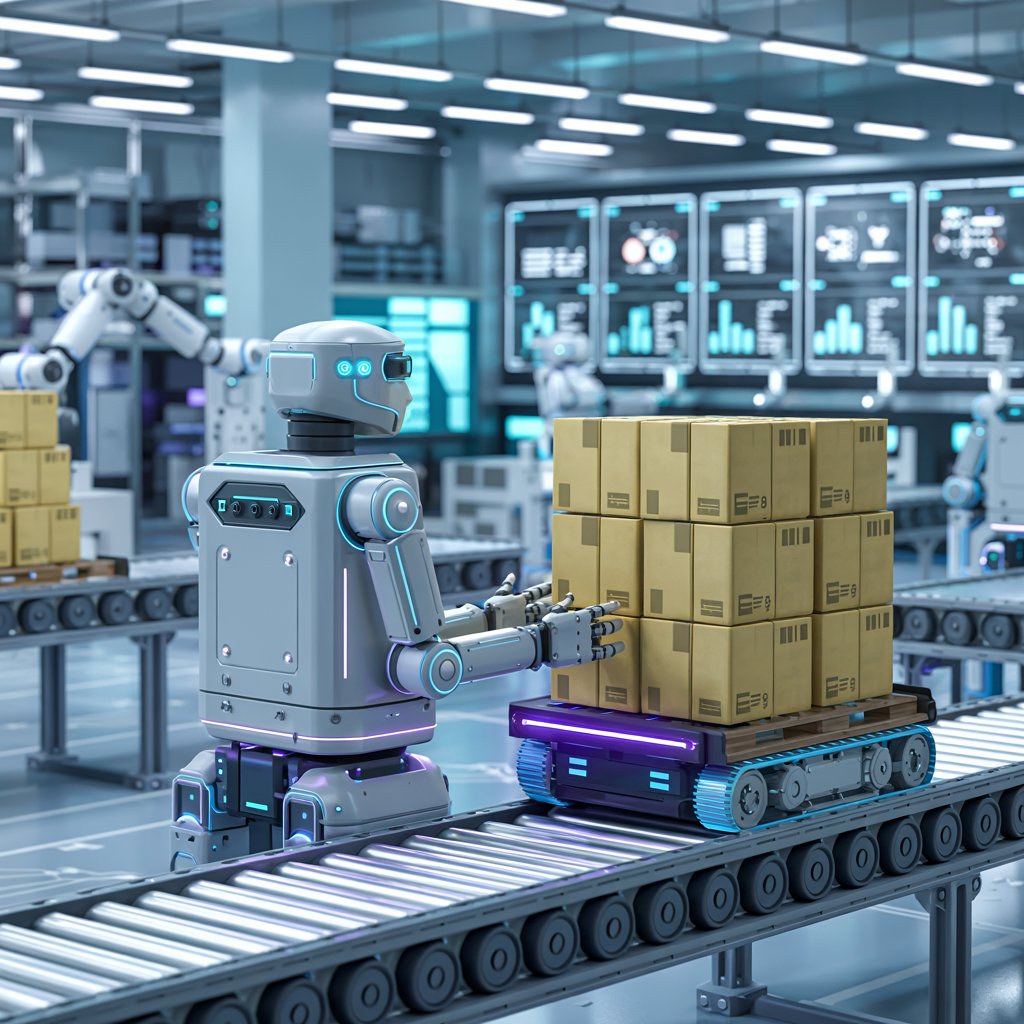

🤖 Types of Warehouse Robots Powering Modern Logistics

Here are the most common robots transforming freight and 3PL operations:

1. Autonomous Mobile Robots (AMRs)

AMRs move goods throughout the warehouse using sensors, maps, and AI.

🟢 Use case: Picking up bins or pallets and navigating to packing or shipping stations without fixed tracks.

2. Automated Guided Vehicles (AGVs)

AGVs follow fixed routes via magnetic strips or tracks, often used in large facilities.

🟢 Use case: Moving high-volume goods from receiving docks to storage zones.

3. Robotic Picking Arms

These robotic arms use machine vision and AI to identify, grasp, and move products—especially useful in e-commerce.

🟢 Use case: Item picking in small bins with speed and precision.

4. Sortation Systems

Conveyor-based systems that automatically sort parcels and items for shipment or storage.

🟢 Use case: High-speed sorting by destination, product type, or weight class.

📦 Real Benefits for Freight and 3PL Companies

Benefit | Description |

⏱️ Faster Fulfillment | Robots reduce pick and pack times dramatically |

📦 Better Inventory Accuracy | Less manual handling means fewer mistakes |

📉 Lower Operating Costs | Savings on labor, errors, and overtime |

🔁 24/7 Operations | Robots don’t need breaks or sleep |

📊 Data-Driven Optimization | Robots generate performance and efficiency metrics continuously |

🧠 The Role of Robotics in WMS Automation

Robotics shines when paired with smart Warehouse Management Systems (WMS). Modern WMS platforms:

- Coordinate robot movements

- Manage inventory data in real time

- Prioritize task assignments for optimal efficiency

- Help scale robotic operations across zones and shifts

Together, WMS + robotics provide the brain and muscle of modern warehouses—turning what used to be manual chaos into coordinated, data-driven precision.

🧭 Future Outlook: The Robot-Driven Warehouse

With the help of AI, IoT, and advanced analytics, robotics in warehousing is evolving beyond movement and into decision-making.

Expect to see:

- Swarms of collaborative robots (cobots)

- AI-based inventory planning

- Predictive maintenance using real-time sensors

- Greater integration across transportation and freight networks

🚀 Final Thoughts

Warehouse robotics is no longer experimental—it’s practical, powerful, and already delivering ROI for freight and 3PL leaders. As the cost of robotics continues to fall and capabilities grow, companies that embrace automation now will dominate the freight landscape of tomorrow.