Reverse-Logistics Forwarding: Streamlining Returns with Freight Forwarding

This is where reverse logistics freight forwarding steps in. It’s the strategic orchestration of return flows using the expertise and infrastructure of a freight forwarder. Done right, it reduces costs, increases customer satisfaction, and unlocks value from what would otherwise be waste.

In this article, we'll break down key elements of reverse logistics—from RMA flows to refurbishment loops—and show how automation can turn return operations into a revenue-generating machine.

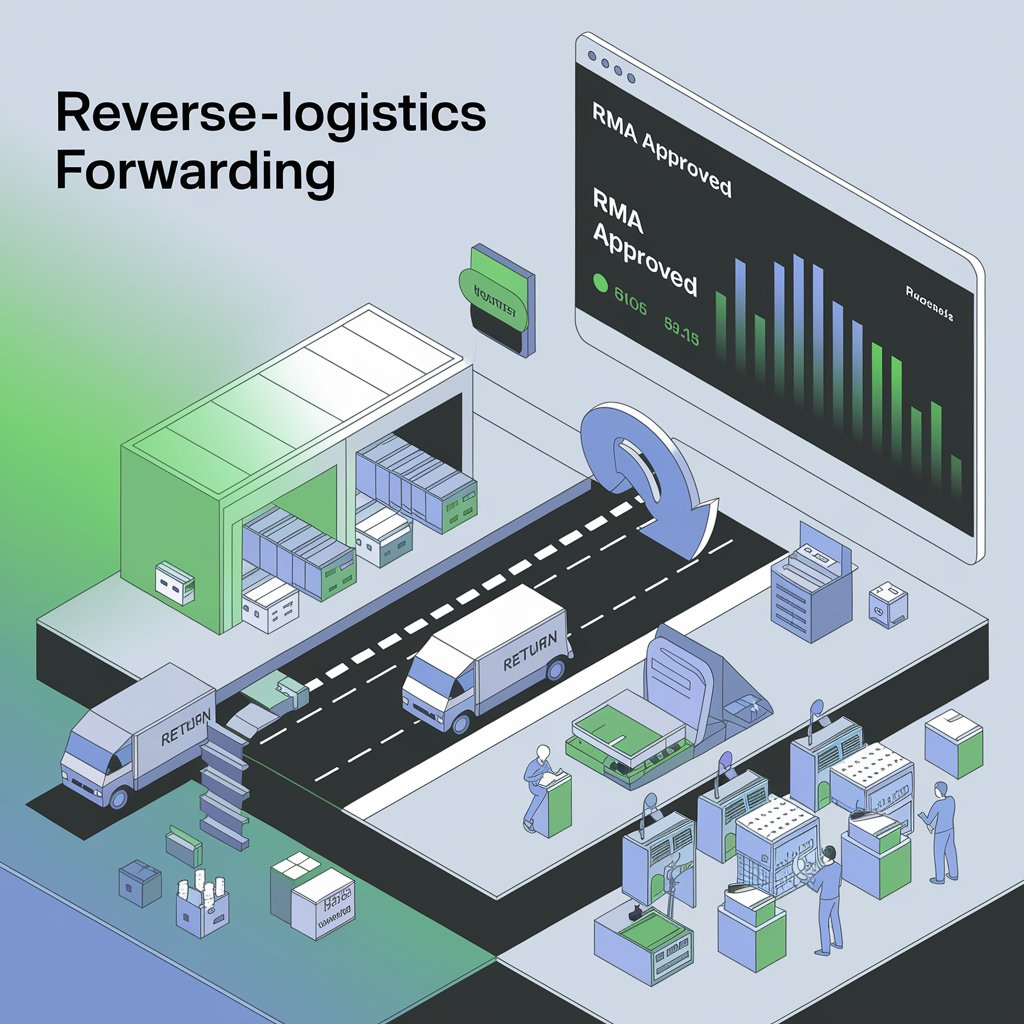

🚚 What Is Reverse Logistics Freight Forwarding?

Reverse logistics freight forwarding refers to the process of managing the return flow of goods from customers back to the seller or manufacturer, using a freight forwarder to optimize and streamline transportation. This includes handling returns, repairs, recycling, and product refurbishments—functions that are critical for industries like electronics, fashion, and e-commerce.

Unlike traditional outbound logistics, reverse freight forwarding is inherently more complex due to:

- Multiple return sources

- Varying conditions of returned goods

- Unpredictable volumes

- Tight processing windows

That’s why businesses are turning to specialized freight forwarders who can manage reverse flows efficiently and cost-effectively.

🔁 The RMA Workflow: A Critical Reverse Logistics Flow

At the heart of reverse logistics freight forwarding lies the RMA (Return Merchandise Authorization) process. Here’s how it typically works:

- Customer Initiates Return: Via a portal, chatbot, or customer service.

- RMA Approval: The system validates eligibility, condition, and warranty.

- Label Creation & Shipping: Freight forwarders generate return labels and coordinate pickup or drop-off.

- Transit Management: Returned items are tracked from the customer’s location to the return hub or refurbishment center.

- Inspection & Processing:

- ✅ Approved: Goes to restocking or refurbishment.

- ❌ Rejected: Disposed of or returned to customer.

📦 Freight forwarders in this loop reduce costs by consolidating returns, providing route optimization, and offering visibility at every step.

🔧 Refurbishment Loops: Extending Product Life Cycles

Returned goods aren’t always the end of the story. Many businesses rely on refurbishment loops to:

- Restore products to like-new condition

- Repackage and reintroduce them to the market

- Extract spare parts for reuse

- Minimize environmental waste

Freight forwarding plays a key role here, ensuring:

- Fast transport to inspection/refurb centers

- Prioritization of high-value returns

- Integration with inventory management for restocking

✅ By closing the loop, companies enhance sustainability while recovering revenue from goods that would otherwise be written off.

📊 See ROI on Returns Automation

Returns are no longer just a cost center—they’re a competitive advantage when automated and optimized.

With reverse logistics freight forwarding solutions, businesses can:

- ⏱️ Reduce return processing times by up to 60%

- 💰 Save 25–40% on shipping costs via consolidation

- ♻️ Recover value from over 30% of returned inventory

😊 Improve customer satisfaction through faster refunds and replacements

🏁 Conclusion: Turn Reverse into Forward Momentum

Reverse logistics isn’t just about getting items back—it’s about getting value back. When combined with the strategic expertise of freight forwarders and automated RMA systems, your return flows can become a source of savings, sustainability, and customer loyalty.

Companies that invest in reverse logistics freight forwarding are already seeing measurable ROI—not just in dollars, but in operational agility and brand perception.

👉 Ready to Transform Your Returns?

See ROI on returns automation.

Automate your RMA flows. Optimize refurbishment loops. Turn logistics into loyalty.

📩 Get a demo or download our returns optimization checklist today!