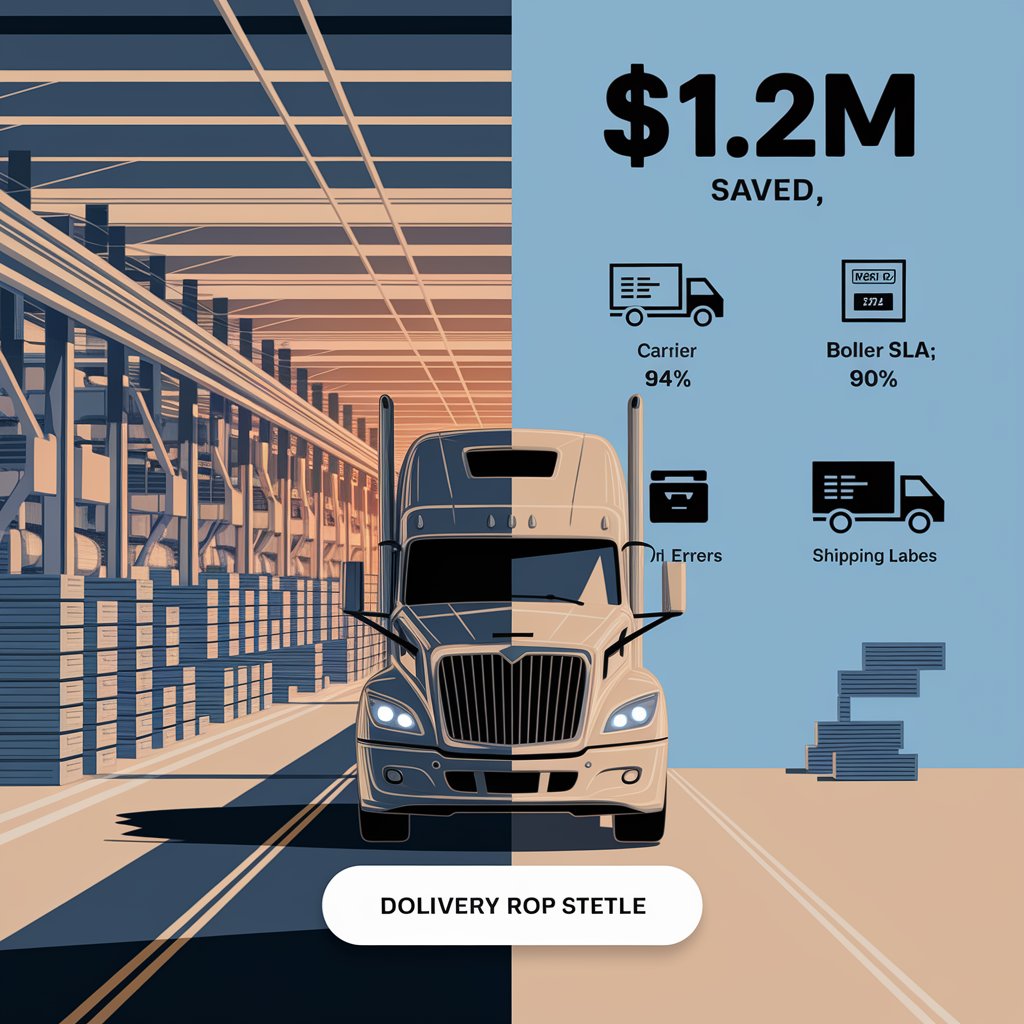

Case Study: Automotive Supplier Saves $1.2M with Linbis

Let’s break down how visibility, automation, and smart cost control drove this major win.

➡️ Download ROI sheet below for full breakdown.

🧩 The Challenge

Axis Components ships hundreds of time-critical parts each week to automakers across North America. Their legacy systems resulted in:

- ❌ Lack of shipment cost visibility across locations

- 📝 Manual BOLs and dispatch planning

- 🔁 No centralized carrier performance tracking

- 💸 Freight overcharges going undetected

They needed a scalable, real-time freight solution to regain control.

🚀 The Solution: Linbis Freight Software

With Linbis, Axis streamlined operations across 4 plants and 2 logistics hubs.

🔄 Real-Time Freight Cost Comparison

- System auto-selects best carrier based on service level + cost

- Weekly savings reports emailed to logistics managers

📥 Automated Documentation

- Auto-generation of BOL, packing lists, and customs docs

- Templates tied to client & order type

📊 Centralized Performance Dashboard

- Carrier on-time %, damage claims, and cost-per-lane tracked in one view

- Triggered alerts for SLA failures

💰 The ROI Results v

Axis Components saw measurable ROI within 5 months:

Metric | Before | After | Change |

Annual Freight Spend | $5.6M | $4.4M | ⬇️ -$1.2M |

Manual BOL Errors (per month) | 42 | 4 | ⬇️ -90% |

Carrier SLA Compliance | 76% | 94% | 🔼 +18 pts |

Time to Quote New Shipment | 20 min avg | 3 min avg | ⏱️ -85% |

🔎 Want the breakdown by plant, carrier, and route?

📄 Download ROI sheet.

📣 Quote from the Client

“Linbis didn’t just digitize our freight — it made our team faster, leaner, and more accountable. We found savings we didn’t even know were leaking.”

— Victor Ramos, Global Logistics Manager at Axis Components

Conclusion automotive freight case study

Axis Components proves that freight software isn’t just for tracking — it’s a profit engine when paired with real data and clear visibility. Linbis helped turn reactive shipping into a strategic advantage.