Logistics Automation 101: Where Freight Companies Should Start

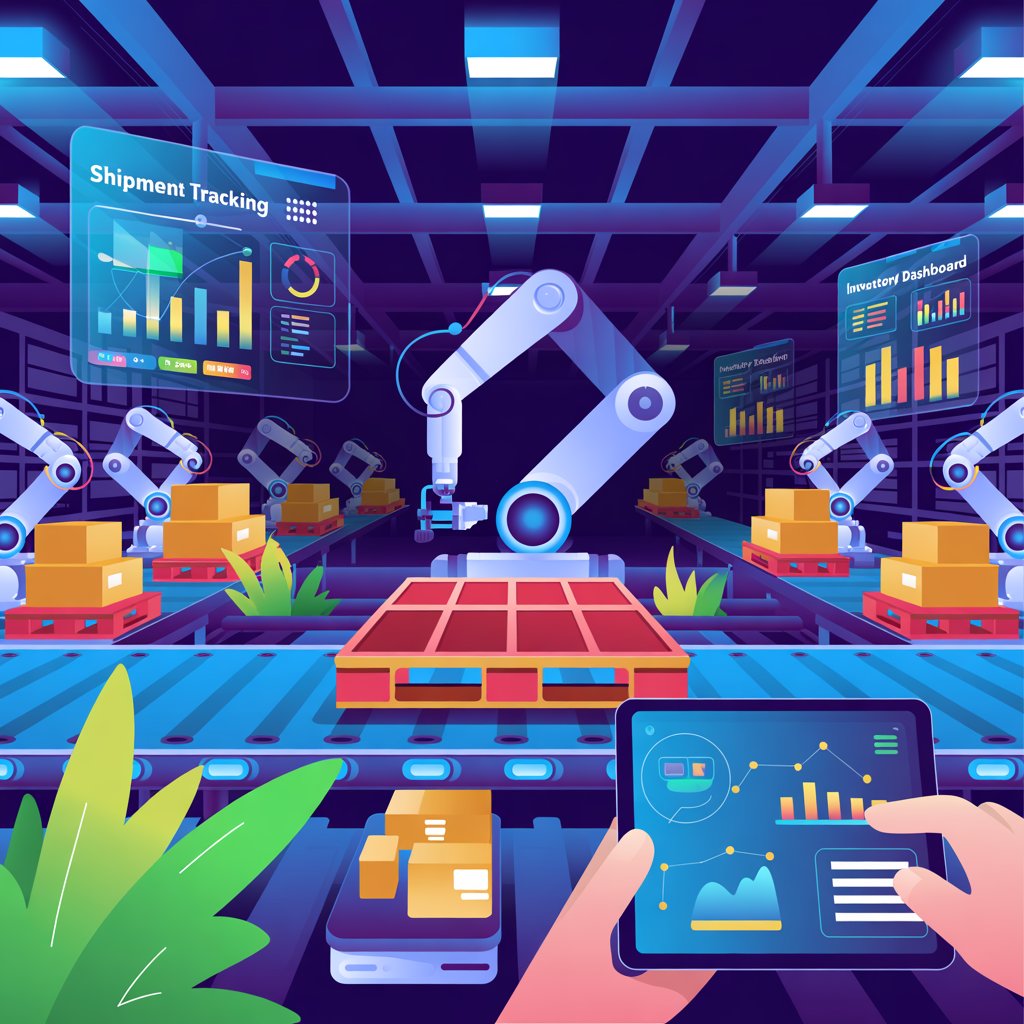

🚚 What Is Logistics Automation?

Logistics automation refers to the use of software, hardware, or robotics to perform logistics tasks with minimal human intervention. These tasks can include:

- Shipment tracking and status updates

- Inventory movement and storage

- Order processing and billing

- Document generation (invoices, customs, BOLs)

- Route planning and carrier selection

The goal: streamline operations, reduce errors, and increase visibility across the supply chain.

🧠 Why Freight Companies Are Automating Now

Here are five big reasons freight and logistics firms are turning to automation:

- Manual processes slow down growth

- Data errors impact customer trust

- Labor shortages make efficiency critical

- Clients expect real-time visibility

- Cost pressures require leaner operations

📌 According to recent industry reports, companies using automation can reduce operational costs by up to 30% and improve order accuracy by over 95%.

🔧 What Can You Automate First?

You don’t need to automate everything at once. Here are starting points that offer fast ROI:

1. Shipment Tracking & Notifications

Automate real-time updates to customers, carriers, and internal teams.

2. Label Printing & Document Generation

Automatically generate and send packing slips, invoices, and customs forms.

3. Order Assignment Rules

Set conditions to automatically route orders by location, service type, or carrier.

4. Inventory Alerts & Reorder Triggers

Trigger restock alerts or auto-purchase orders when levels drop.

5. Customer Communication

Send automated emails or SMS updates on order status and delays.

🔗 The Role of Software in Logistics Automation

Modern freight and logistics platforms include automation features as standard, such as:

- Workflow automation rules

- Custom triggers based on order status

- Integration with carriers, customs, and accounting tools

- Dashboards that show automation performance (time saved, errors avoided)

By centralizing operations in a single platform, companies avoid data silos and streamline the entire fulfillment lifecycle.

💡 Best Practices for Getting Started

- Audit your current workflows — Identify bottlenecks

- Choose one pain point to automate first

- Train your team gradually and monitor results

- Track ROI early — look at time saved, errors avoided, and happier customers

- Use flexible tools that let you scale as your business grows

🚀 Final Thoughts

Logistics automation isn’t just for the big players anymore. With the right software and strategy, freight companies of all sizes can automate key tasks, improve accuracy, and operate with more speed and confidence.

Getting started is the hardest part — but even small steps can lead to big gains.