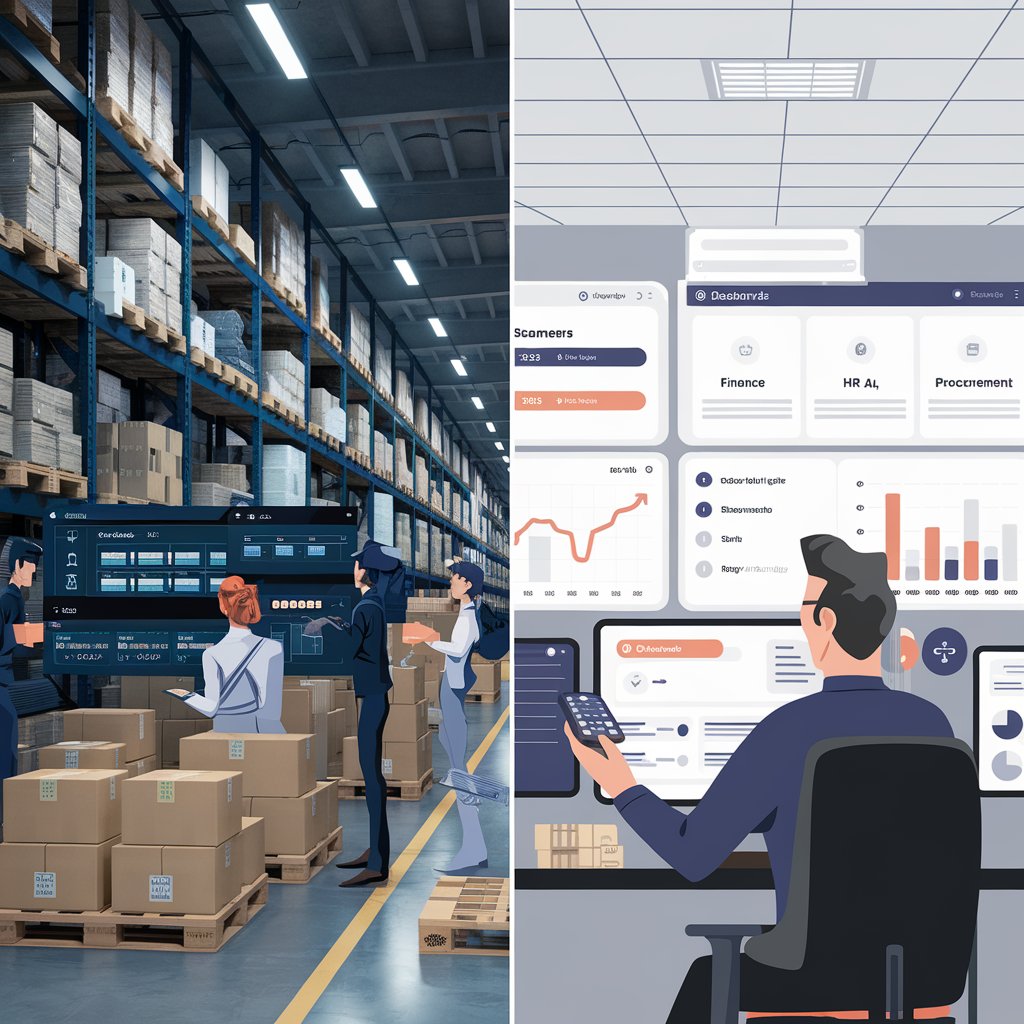

WMS vs. ERP: Differences in Warehouse Management for Logistics

🔍 What Is a WMS (Warehouse Management System)?

A Warehouse Management System (WMS) is software specifically designed to manage and optimize warehouse operations. It focuses on the movement, storage, and tracking of inventory within a warehouse.

Key Features of a WMS:

- Inventory tracking and accuracy

- Order picking and packing workflows

- Receiving and put-away operations

- Real-time visibility of stock

- Barcode and RFID integration

- Task management for warehouse staff

📦 In short, a WMS helps logistics companies streamline every touchpoint inside the warehouse.

🧩 What Is an ERP (Enterprise Resource Planning) System?

An ERP system is a broad business management suite that integrates various functions of a business—like finance, human resources, procurement, CRM, and yes, sometimes basic warehouse features.

Common ERP Modules:

- Accounting and finance

- Sales and customer management

- Purchasing and supplier coordination

- Basic inventory control

- Production planning

💡 ERPs offer a holistic view of the entire organization, often with lighter or generic warehouse tools.

🆚 WMS vs ERP: Key Differences

Feature | WMS | ERP |

Core Focus | Warehouse operations | Business-wide integration |

Inventory Depth | Advanced tracking, real-time updates | Basic stock control |

Customization for Warehousing | High | Limited |

Ideal For | Logistics providers, 3PLs, ecommerce warehouses | Enterprises needing full business integration |

Implementation Time | Faster (modular) | Longer (complex setup) |

Cost | Lower (when stand-alone) | Higher (enterprise licenses) |

👉 If your priority is efficient warehouse operations, a dedicated WMS offers specialized functionality ERPs can’t match.

📦 WMS vs ERP When to Choose a WMS Over ERP for Warehousing?

Choose a WMS like Linbis when:

- You run a logistics company or 3PL that needs granular control over inventory.

- Your warehouse operations are complex and require task automation and scanning tools.

- You need a solution that integrates easily with other platforms (like ecommerce stores or TMS software).

- You want faster ROI and simpler onboarding.

Choose an ERP if:

- You need to unify multiple departments under one system (HR, finance, etc.).

- Warehouse management is not your core focus.

- You’re operating in manufacturing or corporate retail with broader needs.

🚀 Why Linbis Is the Smarter Choice for Warehousing

Linbis is built from the ground up with logistics and warehouse efficiency in mind. Unlike generalized ERP solutions, Linbis offers:

✅ Real-time inventory control

✅ Seamless shipment tracking

✅ Barcode-ready scanning and labeling

✅ Cloud-based accessibility

✅ Integration with customs, freight, and ecommerce tools

By focusing purely on the needs of freight forwarders, logistics providers, and warehouse managers, Linbis avoids the bloat and complexity of ERP systems while giving users exactly what they need to run a lean, efficient warehouse operation.

✍️ Final Thoughts WMS vs ERP

While ERP systems are valuable for managing entire businesses, they often fall short in warehouse-specific workflows. If warehousing is at the heart of your operation, a specialized WMS like Linbis offers unmatched functionality, agility, and ROI.